How To Install Pressure Pump For Washing Machine

What is the perfect water pressure for my RO?

What is the perfect water pressure for my RO?

About revers osmosis membranes are designed to work with 60 PSI or college water pressure, where they are tested to yield a stable rejection charge per unit of at to the lowest degree 97.5%. If the water pressure level feeding an RO system is less than that, the organisation will produce less water and at a lower quality. Additionally, product is reduced whenever the h2o temperature is below 77 °F. Individual well systems almost commonly have pressurized storage tank and pump systems with twenty/40 psi or 30/50 psi on/off pressure level settings. In such cases an electrical pressure boosting pump must be installed to provide adequate rejection of specific health-related contaminants in the feedwater, such equally nitrate or arsenic and others specified by the US EPA or local regulations.

What if I connect my ice maker?

RO water volition produce cleaner ice cubes because of the purity of frozen water. So, connecting your RO to the ice maker makes a lot of sense. However, new water ice makers require 30-40 PSI incoming water force per unit area to function properly. Yous may not have enough pressure at the pressurized h2o tank since your RO cuts the line pressure by 30-35%.

How tin I increase water pressure?

We will discuss several means to boost the pressure level coming out from your cold-water line to run the RO.

Boosting Pressure Using a Permeate Pump

Permeate pumps use the energy of drain water flow from contrary osmosis system every bit leverage to button the purified h2o into the holding tank. Aquatec, the manufacturer of ERP-one thousand permeate pump states that these pumps dramatically improve the efficiency of contrary osmosis h2o (RO) product, reducing wastewater by upward to lxxx%. Permeate pumps can easily be retrofitted to upgrade existing RO systems.

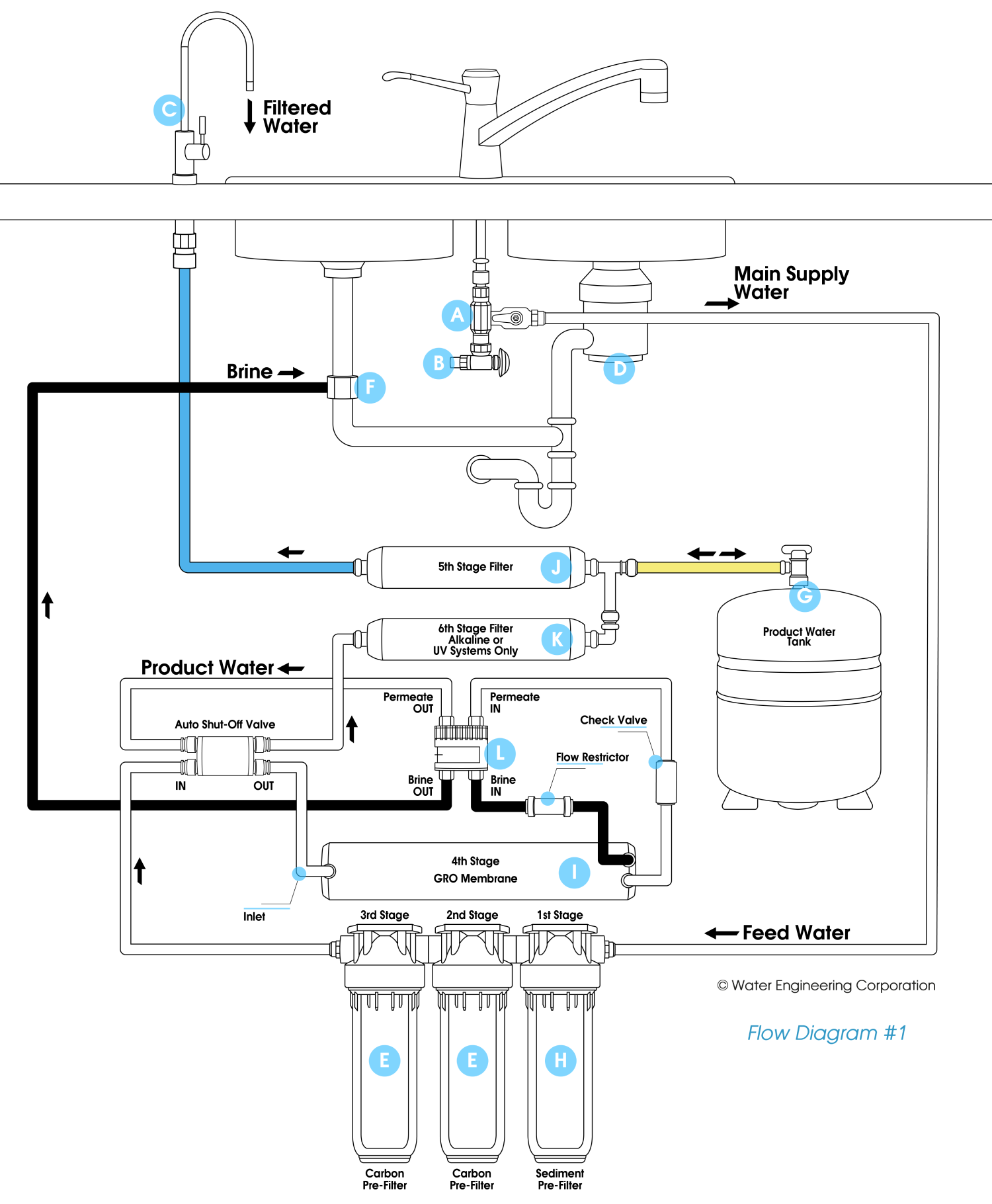

Catamenia Diagram #1

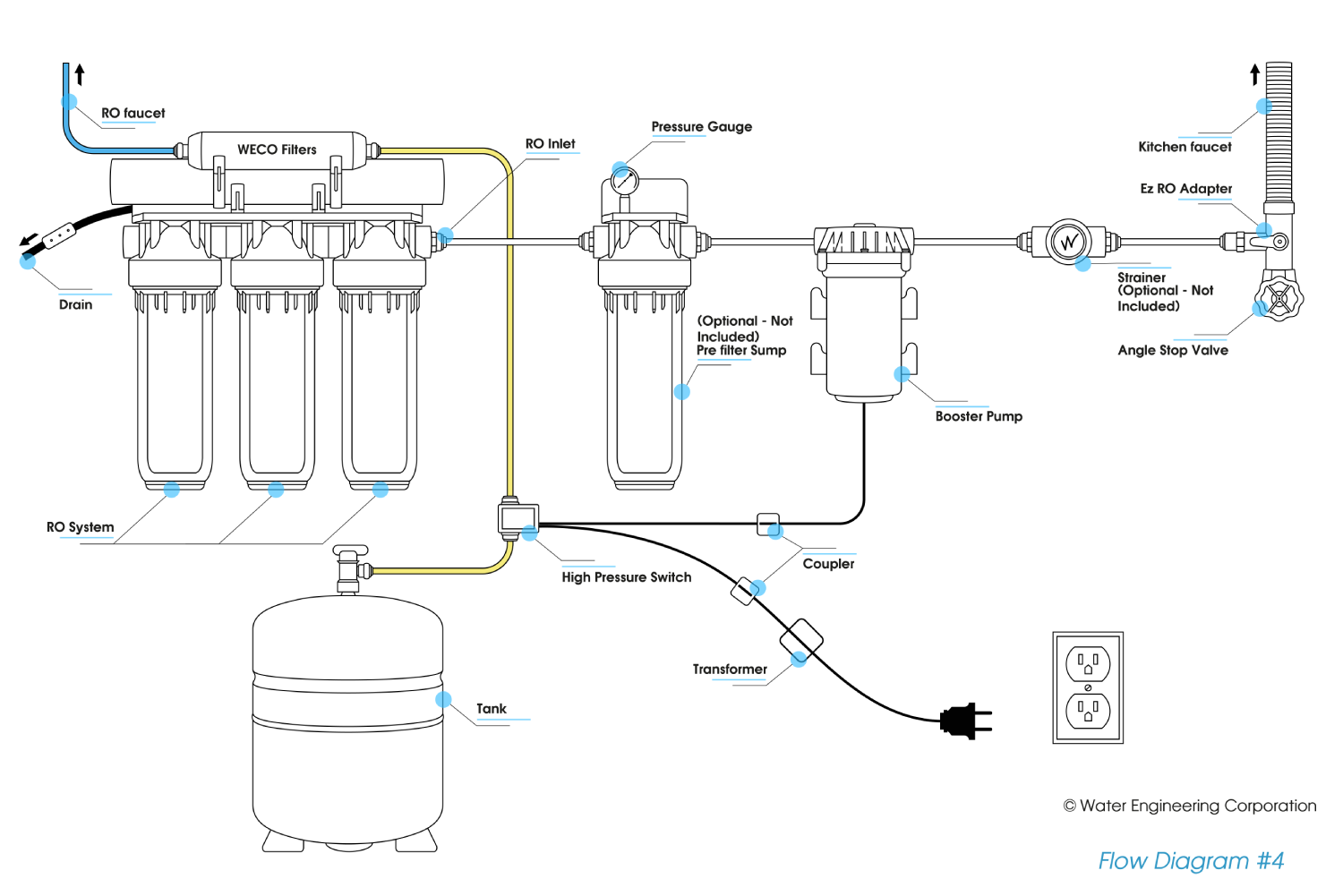

Boosting Force per unit area using an Electric Booster Pump

Calculation an electric booster pump increases the RO product rate, boosts the force per unit area tank storage volume, rejects more contaminants and increases faucet flow rate fifty-fifty if the contrary osmosis membrane force per unit area rating is met by the water supply. Residnetial RO systems work with diaphragm booster pumps that will typically increment the feed pressure upto 75-100 PSI.

Install the pump directly in the RO feed line (see diagrams beneath) following these guidelines.

- A sediment filter should ever protect the pump large particulate matter in h2o. If the blueprint permits, install the pump betwixt the sediment filter and carbon filter since carbon filters before the pump may become besides restrictive of the water flow and starve the pump.

- Pumps must be mounted following suppliers recommendation. Mounting orientations such every bit pump vertical with head down may encourage air-locking, leading to pressure loss.

- Mount the high pressure switch (tank switch) as closest to the tank every bit possible to avoid cycling of pump by reacting to the pressure level drop in the tubing when the drinking water faucet is opened.

- Period of water through the pump is indicated by an pointer. Be sure you insert the tubing correctly.

- If the additional pressure is too loftier (typically >100 PSI), the RO fittings and housings tin can develop leaks. There is a height adjustment screw on the pump caput that tin can be used to lower the pressure level.

What is the perfect water pressure for my RO?

An electric booster pump kit such every bit FC-1400 can very efficienty boost the line pressure up to 80 PSI. This simple low-price setup is the well-nigh commonly used design in residential reverse osmosis industry. A differential pressure controlled automatic close off device (ASO valve) and a high-pressure switch controlls the pump and water flow into the membrane. When the tank pressure gets up to lx% of the incoming force per unit area the valve internally closes off the inlet. This volition build up pressure level on the loftier-force per unit area switch.

FC-1400 kit includes a ane/iv" quick connect ASO valve, pump, transformer and a high-pressure level switch for RO systems upto 50 GPD.

FC-3800 kit includes a 3/eight" quick connect ASO valve, pump, transformer and a high-pressure switch for RO systems upto 100 GPD.

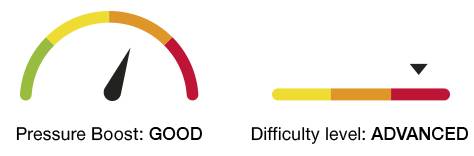

Menstruum Diagram #two

Internal Plumbing - Design 2 Using Solenoid

Most commercial reverse osmosis systems and loftier-end residential ro systems use the following design. Booster pump here is controlled past ii pressure switches. A low-pressure switch at the inlet (activated or conducting current around 5 PSI) makes sure the pump will not run dry. A high-pressure switch (deactivated at 40, 60 or 80 PSI) cuts off power to the pump when the pressurized h2o storage tank has reached the chapters. A solenoid valve stops water supply to the membrane when the pump is off, preventing water running downward the drain continuously. Wiring and plumbing diagrams below. ELCON-24 kit includes the solenoid, pump, transformer and high/depression pressure switches.

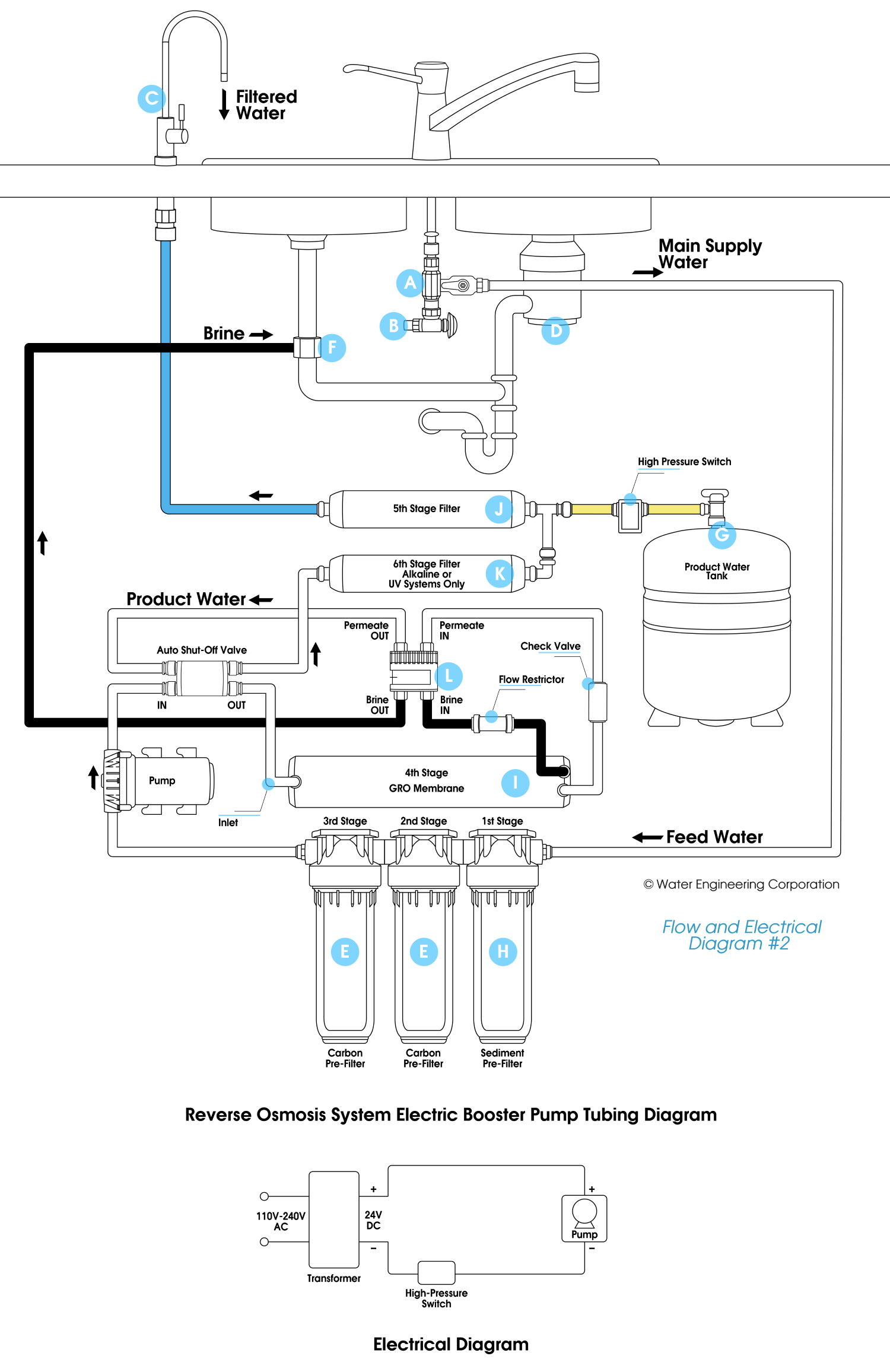

Flow Diagram #three

Like shooting fish in a barrel External Plumbing - Design 3

Design below requires no internal plumbing modifications on your RO system. Simply mountain the booster pump betwixt the water supply and the RO. A high pressure switch will mount on the pressurized storage tank tubing. This pressure level switch cuts off power to the pump when the water storage tank reaches forty PSI (or rated pre gear up pressure of the switch).

Our economy pump retrofit kits ECON-50P utilize this design. Premium retrofit kit GYC-1400 also includes a pressure gauge organisation with a pre-filter pressure stabilizer as well as a strainer to protect the pump from sediment. Video below illustrates installing of the premium kit.

Menstruation Diagram #4

Source: https://www.wecofilters.com/blog/post/booster-pump-installation

Posted by: pickettfelonfuld.blogspot.com

0 Response to "How To Install Pressure Pump For Washing Machine"

Post a Comment